Kardboard is my son Andrew's Bell Hinged back Tortoise. We estimate that he is anywhere from 7 - 12 years old. We recently found out that these tortoises can live up to 50 years with the right treatment. Unfortunately for the past few years the tortoise has survived in an environment that has been less than optimal for his health and well-being. Though he is not in ill-health, he is also not flourishing.

I recently decided to remedy that. I built this new enclosure with remnants from Kardboard's much larger enclosure that we previously abandoned. Everything is handmade by me. It's interior dimensions are 34" x 15" x 12" crafted from 1" x 6" hardwood and a 3/8" exterior plywood bottom. All surfaces have been coated with a water-based non-toxic paint and water-based polyurethane varnish. The side panels are 1/4" acrylic plastic held in place with silicone caulking.

The

small box inside the enclosure is a hide box

The enclosure's top is now crafted out of 1/4" Lexan with closely-meshed poultry wire (as a kid we called it chicken wire) in the areas where the lights and heater come in contact with the top. 3/4" aluminum angle irons and straight irons form the frame. Its all held together with rivets. I'm kind of proud of the way it came out.

The light stands are simply standards and brackets which I affixed to the back of the enclosure with a neat little wood blocking system which allows them to be removed by un-tightening some wing nuts. I actually thought of a more flexible way of doing it by utilizing some t-channels and t-locknuts but did not employ them to keep the cost down (everything except the chicken wire and angle irons I had on hand).

I am heating the habitat with (1) 150 Ceramic Heat Emitter and incandescent lights (2 60 watt bulbs). The animal requires three distinct heat ranges/zones. During the day the enclosure's temperature should be between 85-90*F. When basking - 95*f. Evening temperature should be between 75-80*f.

Lighting comes from a 24" full UVB Fluorescent fixture which sits on the top cover and two (2) 60 watt incandescent bulbs The light cycle encompasses 12 hour day and night cycles controlled by a simple digital timer.

Humidity is kept in a 50 - 70% range controlled by a home crafted misting system which utilizes a five (5) gallon bucket, an automotive windshield washer mini pump and misting nozzles procured from Barr.

Control System

Control of the temperature and humidity is handled by a Basic Stamp Processor which forms the nucleus of computerized environment control system. A temperature/humidity sensor constantly feeds temp and humidity data to the basic stamp which automatically adjusts the heating and misting cycles to achieve the prescribed ranges.

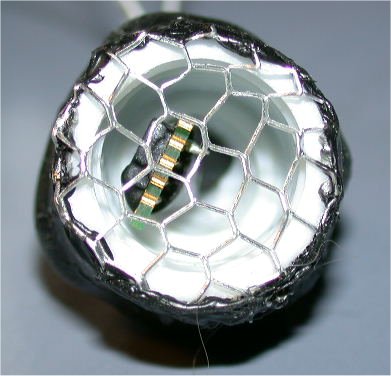

I am currently employing a Parallax Basic Stamp 2 as the system processor. The control circuitry takes data from the temperature/humidity sensor, (Thank you Nuts & Bolts for the basic code and sensor circuit setup). Based upon the temperature and humidity data, the system processor will send control signals to the rest of the system. The Sensirion SHT11x sensor is a tiny, reasonably low-cost sensor with very excellent accuracy. Though it is an SMD chip format I soldered wires directly to the sensor carrier board and then enclosed it in a protective shell to shield it from direct contact with water and a nosey tortoise. Its not very pretty but it should work nicely.

The other active parts to the system are the temperature/heating system and the humidity system.

For heating I have employed one 150 watt ceramic heating emitter supplemented during daylight hours by two (2) 60 Watt incandescent light bulbs. I keep the temperature in the range 27C - 30C. I am using a simple circuit to accomplish this. Using one of the basic stamps I/O ports I send a high (on) or low (off) signal to the base of a NPN transistor (PN2222A). This is done to better isolate the Stamp processor chip from the relay circuitry. When a high (on) signal is sent to the transistor's base the electricity is allowed to flow from the collector the the drain side of the circuit, which energizes the coil of the relay's normally-open circuit now closing it. This allows the 110vac juice to flow and allow the emitters to glow. The relay is a Radioshack (part no 275-0248), 12vdc coil, 10amp 110vac relay which should be more than enough to meet the 2.75amp draw the 150 watt emitter.

The Humidity system is another Rube-Goldberg of mine with design and insight coming from the hard work of others on the net. Here the Stamp processor again sends High (On) or Low (Off) signals to a MOSFET transistor. The Mosfet (IRZ34N) is a fast switching, high amp, high voltage IC to handle the rigors of the pump starts and stops. When the gate of the Mosfet is sent a High signal it allows 12vdc to flow between its source and drain, thus closing the circuit and allow 12vdc to reach the pump. The pump is a mini-windshield washer pump (from allelectronics) which is fed by a five gallon bucket. The output of the pump goes to a set of misting heads, via tubing, that was procured from (Barr).

The floor of the enclosure will contain a substrate comprised of forest base and other elements. I hope to add some parsley and other type herb plants for Kardboard to browse.

Update: 01/15/2005

Over the summer and fall of this year I re-engineered the cover of the enclosure replacing most of the screening with 1/4" Lexan sheet. This has allowed me to much better control the humidity using the sensor monitoring system. The humidity now easily stays in the 50-60% range with the misting system being activated by the processor when needed. In addition I have provided a hatch door for feeding and cleaning the tank. All in all Kardboard seems to be healthy and definitely more active.

Kardboard is now in his new habitat and seems delighted and much much happier and active. He has better light, more room, a great substrata to walk on, and a nice new hide box.